The creative agency landscape is being transformed by DTF (Direct-to-Fabric) Technology, a printing solution that offers efficient, high-quality results on diverse materials. This technology democratizes design, allowing small studios to produce custom logos and artwork easily. By streamlining production, reducing waste, and ensuring consistent quality, DTF enhances agency service offerings and keeps them competitive. Its key benefits include direct printing on dark fabrics, faster production times, superior image quality, and reduced setup time, making it a popular choice across sectors like fashion, sports teams, and promotional merchandise.

Creative agencies are increasingly embracing DTF Technology as a game-changer in their design-to-print processes. This shift, driven by the need for enhanced efficiency, accuracy, and sustainability, is transforming how agencies operate in today’s competitive landscape. In this article, we delve into the benefits of DTF Technology, explore successful case studies, and examine its role in future-proofing creative agencies through automation, AI, and emerging trends.

- The Shift to DTF Technology in Creative Agencies

- – Exploring the benefits and drivers behind the adoption of Direct To Format (DTF) technology

- – Case studies of successful implementations

The Shift to DTF Technology in Creative Agencies

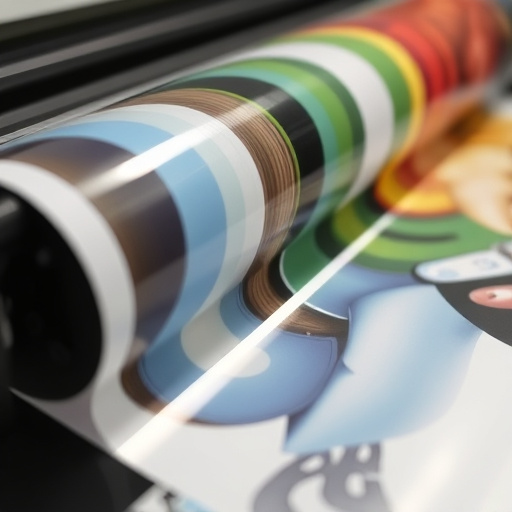

The creative agency landscape is undergoing a significant transformation as professionals recognize the immense benefits of embracing Digital Transfer Film (DTF) technology. This shift is driven by the need for efficient, high-quality printing solutions that can keep up with the demands of modern branding and design. DTF Technology offers a game-changer in this regard, providing agencies with a versatile tool to create intricate designs on various materials, from textiles to wood and metal.

With advancements in technology, DTF printers, considered among the best for precision and speed, are now accessible to even small creative studios. This accessibility has democratized design, enabling clothing brands and designers to produce custom logos and artwork using DTF for clothing and other products. The process streamlines production, reduces waste, and ensures consistent quality, making it an attractive option for agencies looking to enhance their service offerings while staying competitive in the market.

– Exploring the benefits and drivers behind the adoption of Direct To Format (DTF) technology

Direct To Format (DTF) technology is transforming the creative agency landscape by offering an efficient and versatile solution for printing on various surfaces. The adoption of DTF has been driven by several key benefits, particularly in the context of modern design and manufacturing demands. One of the primary advantages is its capability to produce high-quality prints directly onto materials without the need for intermediate steps like film positives or plate preparation. This not only streamlines production but also enhances accuracy and reduces waste, making it an eco-friendly option.

Moreover, DTF technology allows creative agencies to expand their service offerings, especially in the realm of custom printing on dark fabrics. With a dtf printer, agencies can effortlessly create intricate designs and detailed transfers for clothing, accessories, and other textiles, catering to diverse client needs. This advanced printing method promises faster turnaround times, superior image quality, and increased customer satisfaction, solidifying its position as a game-changer in the industry.

– Case studies of successful implementations

Creative agencies are increasingly turning to DTF (Direct-to-Fabric) technology as a game-changer in their print solutions. This innovative process has transformed the apparel industry, enabling complex and high-quality designs on a variety of fabrics with remarkable efficiency. Case studies reveal successful implementations where DTF has revolutionized custom apparel production. For instance, a leading fashion brand utilized DTF printing for hoodies, achieving stunning, intricate patterns that traditionally would have been cost-prohibitive with other methods.

The technology’s versatility is evident in its application across diverse sectors. From fashion to sports teams and even promotional merchandise, DTF has proven its worth as a reliable and fast solution. In many cases, it offers significant advantages over traditional printing methods, including reduced setup time, minimal waste, and the ability to print on unique fabric shapes and sizes. This has led to increased productivity and satisfied clients in numerous successful DTF for apparel projects.

Creative agencies are increasingly adopting DTF Technology as a game-changer in their operations. By eliminating intermediate steps and enabling direct printing to various formats, DTF offers enhanced efficiency, cost savings, and improved quality. As seen from successful case studies, this technology revolutionizes the way agencies handle projects, fostering faster turnaround times and higher client satisfaction. Embracing DTF Technology is thus a strategic move for creative professionals to stay ahead in today’s competitive market.