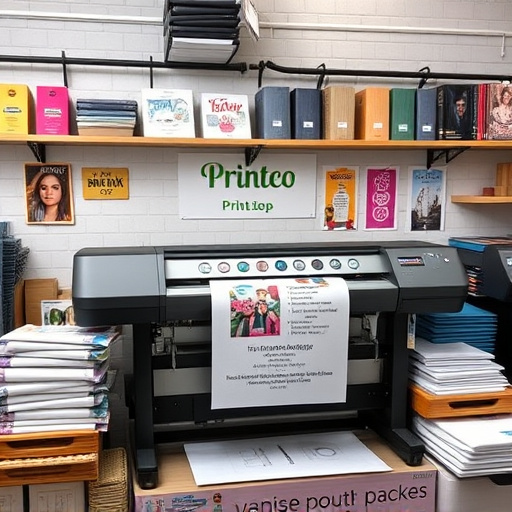

DTF Technology has revolutionized manufacturing with unprecedented speed and flexibility. It streamlines apparel production by enabling rapid prototyping, small-batch DTF shirt manufacturing, and easy customization using heat press machines. This method significantly reduces lead times, allows for personalized designs, and enhances print quality on various materials, including dark fabrics. By eliminating intricate setup procedures, DTF Technology offers faster, more efficient results compared to traditional printing methods, giving businesses a competitive edge in today's fast-paced industry.

In today’s competitive market, manufacturing industries are constantly seeking ways to unlock unparalleled speed and agility. Enter DTF Technology, a game-changer that is revolutionizing production processes. This innovative approach offers unprecedented flexibility, enabling manufacturers to adapt swiftly to evolving demands. By streamlining operations, DTF Technology enhances efficiency, reduces time, and minimizes waste. Discover how this cutting-edge technology is transforming manufacturing, from unlocking rapid turnaround times to fostering a more responsive and agile production environment.

- Unlocking Speed and Agility in Manufacturing

- DTF's Flexibility Revolutionizes Production

- Streamlining Processes for Efficient Results

Unlocking Speed and Agility in Manufacturing

The advent of DTF Technology has unlocked unprecedented speed and agility in manufacturing, transforming the way industries approach production. This innovative process allows for rapid prototyping and small-batch production, eliminating the need for extensive set-up times associated with traditional printing methods. By enabling on-demand printing, DTF Technology empowers manufacturers to swiftly adapt to market trends and customer demands.

For apparel producers, this translates to facilitating the bulk DFT shirt production, where custom designs can be effortlessly integrated into the manufacturing process. The technology streamlines the application of DTF transfers using heat press machines, ensuring a seamless and efficient workflow from design to finished product. This agility not only reduces lead times but also opens doors for brands to offer personalized, unique garments at competitive rates.

DTF's Flexibility Revolutionizes Production

The DTF Technology is revolutionizing production lines with its unparalleled flexibility. This innovative process allows manufacturers to adapt quickly to changing market demands and trends, a significant shift from traditional methods that often require lengthy set-up times for customization. With DTF heat transfer paper, printers can effortlessly switch between designs and colors, catering to diverse customer preferences.

DTF printing for dark fabrics, in particular, has been a game-changer. It ensures vibrant, lasting prints on previously challenging fabric types, opening up new design possibilities. The technology’s efficiency means that complex patterns and detailed dtf transfers can be produced promptly, enhancing overall production speed without compromising on quality.

Streamlining Processes for Efficient Results

The adoption of DTF (Direct to Fabric) Technology has revolutionized the way production processes are streamlined, leading to more efficient and faster results. This innovative approach eliminates the need for intricate setup and plate preparation, which is a significant time-saver compared to traditional printing methods. With DTF transfers, manufacturers can achieve exceptional print quality on a wide range of materials, from light-colored fabrics to dark tones, previously considered challenging.

This technology streamlines the entire process, from design to final product, by enabling precise and direct application of ink onto the fabric surface using heat press machines. The precision and speed of DTF printing ensure that businesses can meet market demands for rapid production runs while maintaining high-quality standards, giving them a competitive edge in today’s fast-paced industry.

DTF Technology is transforming manufacturing by offering unprecedented speed, flexibility, and efficiency. By unlocking new levels of agility in production processes, DTF enables businesses to adapt swiftly to market demands and stay ahead of the competition. Through streamlined workflows and innovative solutions, this technology revolutionizes the way we think about manufacturing, paving the way for a future where production is both faster and more versatile.