DTF Technology (Direct to Fabric) is revolutionizing apparel design and production with unprecedented creativity, speed, and efficiency. It removes limitations from traditional printing methods, allowing designers to bring diverse visions to life on custom garments. DTF empowers brands to explore new aesthetics, experiment with materials, and swiftly deliver unique designs to market, fostering a vibrant tapestry of creative expression in clothing production. By bypassing intermediate steps and directly transferring designs onto fabrics, DTF offers speed, precision, waste reduction, and lower labor costs compared to traditional methods. In today's competitive market, it's transforming the industry by enabling mass customization of clothing with intricate patterns in record time.

DTF (Direct-to-Fabric) Technology is reshaping the apparel industry, offering a game-changing approach to design, production, and consumer engagement. This innovative process allows for unprecedented creative freedom, enabling designers to bring unique, personalized garments to market faster. By streamlining production and catering to rising demand for customization, DTF Technology enhances efficiency while fulfilling consumers’ desire for distinctive, tailored pieces. Discover how this cutting-edge method is revolutionizing the way we create and experience apparel.

- Revolutionizing Apparel Design: DTF's Creative Potential

- Streamlining Production: Efficiency Through DTF Technology

- Consumer Demand Met: Customization and Personalization with DTF

Revolutionizing Apparel Design: DTF's Creative Potential

DTF Technology is unlocking a new realm of creativity in apparel design, revolutionizing the way we create and personalize clothing. This innovative process allows designers to bring their visions to life with unprecedented versatility and speed. With DTF (Direct-to-Fabric) methods, the possibilities are endless; from intricate graphics and bold typography to complex photo-realistic images, DTF heat transfer paper and transfer films enable the production of custom t-shirts and other garments that were once thought impossible.

By eliminating many of the constraints associated with traditional printing methods, DTF offers a game-changing approach to apparel innovation. It empowers designers and brands to explore new aesthetic directions, experiment with diverse materials, and deliver unique, on-trend designs to market promptly. This technology is reshaping the industry, fostering a vibrant tapestry of creative expression in clothing design and production.

Streamlining Production: Efficiency Through DTF Technology

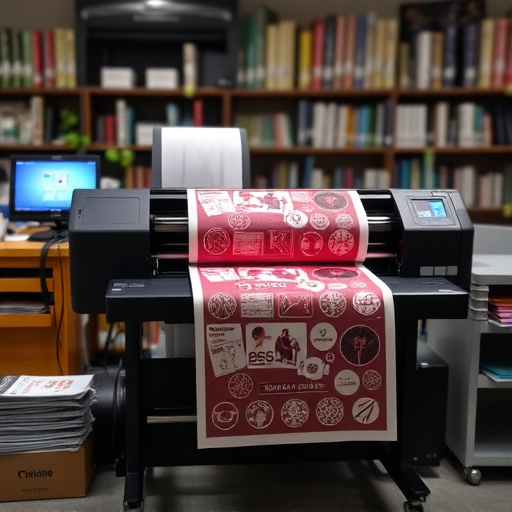

DTF (Direct to Fabric) Technology has revolutionized apparel production by significantly streamlining and enhancing efficiency. This innovative approach eliminates the need for costly intermediate steps, such as printing on paper or vinyl transfers, which are then applied to fabric. Instead, DTF printers directly transfer designs onto various materials, including light fabrics commonly used in t-shirts and other garments. The process is both faster and more precise, reducing waste and labor costs associated with traditional methods.

One of the standout benefits of DTF Technology is its versatility. It allows for intricate and detailed designs to be achieved with ease, making it ideal for custom apparel and small batch production. Moreover, the cold peel feature of certain DTF transfers ensures a smooth finish and easy removal from the fabric, further streamlining the production line and enabling faster turnaround times without compromising on quality.

Consumer Demand Met: Customization and Personalization with DTF

In today’s fast-paced world, consumers are increasingly demanding personalized and customized apparel that reflects their unique styles and preferences. DTF (Direct to Fabric) Technology rises to this challenge by offering unparalleled levels of customization and personalization in the apparel industry. With DTF, designers and manufacturers can swiftly create custom t shirts with intricate designs and detailed graphics, catering directly to individual consumer tastes.

The integration of DTF into bulk DFT shirt production processes streamlines the creation of customized products, making it an efficient solution for both small-scale and large-scale apparel brands. DTF transfer sheets, loaded with vibrant inks, enable the application of designs onto various fabrics with precision and accuracy. This technology democratizes access to personalized apparel, allowing for on-demand production and satisfying the ever-evolving demands of modern consumers who seek distinctive, tailored pieces that stand out from the crowd.

DTF Technology is not just a trend; it’s a disruptive force transforming the apparel industry. By revolutionizing design, streamlining production, and catering to consumer demand for customization, DTF offers a comprehensive approach to innovation. As we look ahead, embracing this technology is crucial for brands aiming to stay competitive and meet the evolving needs of modern consumers.