DTF Technology is a groundbreaking direct-to-film transfer method that has disrupted the textile industry by offering exceptional print quality, durability, and versatility for custom apparel. This technique enables precise, vibrant printing on fabrics like cotton, polyester, and nylon using specialized equipment and ink, eliminating traditional screening. Ideal for personalized hoodies and other garments, DTF Technology provides long-lasting, crisp designs resistant to washing and sunlight. Its advanced inks and transfer sheets cater to diverse fabric types, making it a preferred choice for businesses aiming to offer high-quality, personalized products. With promising advancements, DTF Technology is set to revolutionize custom apparel production by allowing intricate designs and fine details on a broader fabric spectrum.

“Discover the future of printing with DTF (Direct to Film) Technology—a revolutionary method transforming the way we create durable and vibrant visuals. This cutting-edge process offers unparalleled advantages for long-lasting, high-quality prints, making it a game-changer in various industries. From its seamless application on diverse surfaces to its ability to capture intricate details, DTF technology is reshaping the landscape of print. Explore how this innovative approach is fostering creativity and enhancing visual experiences across multiple sectors.”

- Understanding DTF Technology: A Revolutionary Print Method

- Advantages of DTF for Long-Lasting and High-Quality Prints

- Applications and Future Prospects of DTF Technology

Understanding DTF Technology: A Revolutionary Print Method

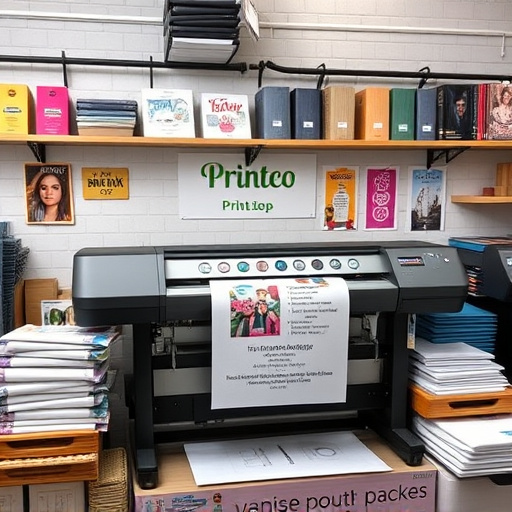

DTF Technology is a revolutionary print method that has transformed the textile industry by offering exceptional quality and durability in custom apparel. This cutting-edge technique, short for Direct to Film Transfer, allows for precise and vibrant printing directly onto fabric using specialized equipment and ink. By eliminating the need for traditional screening or plate preparation, DTF enables the production of highly detailed, long-lasting designs on various materials, including cotton, polyester, and nylon.

With its advanced capabilities, DTF is particularly favored for creating personalized hoodies, ensuring each piece boasts a unique and vivid print. The process involves precisely aligning the design with the fabric, followed by heat press or UV curing to permanently set the ink. This method not only delivers crisp, colorful images but also enhances the overall aesthetic appeal of textiles, making it a top choice for those seeking high-quality, custom DTF printing on t-shirts and other garments.

Advantages of DTF for Long-Lasting and High-Quality Prints

DTF Technology offers a host of advantages for achieving long-lasting and high-quality prints. One of its key strengths is the durability of the final product. DTF (Direct to Fabric) prints are designed to withstand wear and tear, making them ideal for items that see frequent use or exposure to various elements. The inks used in DTF technology are specifically formulated to adhere strongly to fabrics, ensuring that colors remain vibrant even after repeated washing and prolonged sunlight exposure.

Additionally, DTF transfer sheets provide a level of versatility that enhances their utility. These sheets can be applied to a wide range of fabric types and surfaces, allowing for custom designs on everything from t-shirts and hats to home decor items like cushions and tablecloths. This versatility makes DTF an attractive option for businesses looking to cater to diverse customer preferences while maintaining consistent print quality.

Applications and Future Prospects of DTF Technology

The applications of DTF Technology are vast and continue to expand across various industries, with a significant focus on apparel. This innovative printing method has revolutionized the way designers and manufacturers create custom garments, offering unparalleled versatility and quality. DTF is particularly suited for dtf printing for light fabrics due to its ability to produce vibrant, long-lasting prints on delicate materials without causing any damage or fading. It’s not just limited to dtf for t-shirts, but also extends to a range of apparel items, from dresses and skirts to hoodies and caps.

Looking ahead, the future prospects of DTF Technology appear promising, with potential implications in several areas. As the technology continues to evolve, we can expect even more advanced printing capabilities, enabling intricate designs and fine details on a broader spectrum of fabrics. This will further enhance its appeal in the apparel industry, where staying ahead of trends and offering unique, personalized pieces is paramount. With its capacity to deliver high-quality prints at competitive speeds, DTF Technology is poised to disrupt traditional printing methods and shape the future of custom apparel production.

DTF Technology has emerged as a game-changer in the printing industry, offering durable and vivid solutions for various applications. Its advantages are clear: exceptional longevity, superior color accuracy, and a versatile range of materials. As we look to the future, DTF’s potential is set to unfold across diverse sectors, from apparel and signage to promotional products and art reproductions. This innovative print method promises to continue enhancing our visual landscape, ensuring that vibrant, long-lasting images are within reach for years to come.